Chucks

Chucks are defined as special types of clamps that hold those tools and materials together that are rotating in nature.As a reputed manufacturer, exporter and trader, we offer a comprehensive range of industrial chucks that includes 3-4 jaw self centering chucks, 4-jaw Independent Dog chucks, Face Plate Jaws, Taper 3 jaw self centering chucks, 2 jaw screw operated self centering chucks, dust proof special chucks, chucks with back plates, base hard top soft jaws, six jaw chucks, bearing chucks, etc. With an experience of 50 years, the company has surged ahead to become the most respected entity in its field.tandem with the latest technology.

1. STANDARD JAWS CHUCKS :

These Chucks are widely used on Lathes, Rotary Tables, Dividing heads etc. The most popular semi-steel body Chucks supplied with forward and reverse (SJ Type) and (Forward, Forward Jaws, SSJ Type) set of jaws, mounting bolts and operating key. SJ Type Chucks available in 60, 80, 110, 120, 160, 200, 250, 270, 315, 350, 400, 450, 500, 600, 630 mm sizes in 2, 3, 4 & 6 Jaws

2. RING CHUCKS :

Chucks for Ring Turning, BRJ Type

This model is specially designed for Ring Turning with special type of jaws

which is more useful for the manufacturer of ball bearings & Ring Type job.

This Chuck is having two types of Jaws (for different sized Rings), Mounting Bolts & operating key.

This model is also available with set of Jaws having inside gripping capacity of Dia 25mm.

Available sizes are 160mm, 200mm, 250mm, 300mm in 3, 4 & 6 Jaws

3. CRANK SHAFT CHUCKS :

Chucks for Crank Shafts Grinders CRJ Type

Semi Steel Body CRJ Type Chuck is specially designed to provide stronger grip

for crank shafts which is most suitable for crank shafts grinder machines.

These Chucks are having forward & reverse set of jaws (Gripping Face serrated),

operating key and mounting bolts. Available size 160mm, 200, 250mm in 3 and 4 Jaws.

4. MASTER JAWS CHUCKS :

Chucks for Master Jaws MTJ Type

Master Gripping Semi Steel Body Chuck is designed into two parts of Jaws

(or Split Type Jaws) one is master Jaw (Base Jaw) and the other is Top Jaw.

The Top Jaw is fitted on Base Jaw with Allen Bolts.

This Top Jaw have reversible function i.e. Forward Jaw as well as reverse Jaw

when fitted alternatively i.e. even a single of hard Jaw (Top Jaw) allows

Chucking both inside and outside diameters. The Top Hard Jaws for Heavy cutting,

Top Soft Jaws, ideal for precise finish. This chuck supplied with top

hard reversible jaws set and a set of top soft jaws mounting bolts and

operating key. MTJ Type Chucks are available in 160mm, 200mm, 250mm sizes in 3 & 4 Jaws.

5. LEVER OPERATED CHUCKS :

Glass Blowing Lever Type

These Light weight Semi steel body Chucks are suitable for small precision lathes,

light grinding machines, glass working lathes. Thin section components may be

held without distortion.These Chucks supplied with forward and reverse set of Jaws,

mounting bolts and operating key.

Available in 50mm, 65mm, 75mm, 85mm, 100mm, 110mm BORE sizes in 3 & 4 Jaws.

Also available set of Jaws having base hard, Top Soft Jaws mounted together with Allen Bolts.

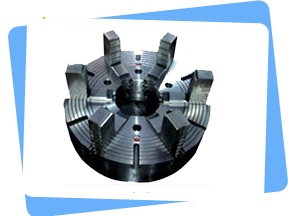

6. SIX JAWS TURE CHUCKS

We are a prominent organization that is engaged in manufacturing and exporting Six Jaw Chuck. Chucks are used to hold the material and tools together of rotating nature, ensuring smooth flow of work. Our fabricated chucks are used in various industries for quick and easy completion of various works. These chucks are made in strict compliance with the international standards. Customers can avail this Six Jaw Chuck from us as per their demands and requirements.

7. INDEPENDENT CHUCKS

Heavy Duty chucks refereed as HD, are suitable for normal working conditions. However these chucks will stand well ahead in Quality, Load carrying capacity and Life if compared with other competitive brands available in the market. Where other brands of chucks fail to give service, our chucks will give trouble free service for long period. The jaw-ways in body are of robust proportion which can withstand heavy loads. The diameter of screws is large enough to tolerate heavy cutting pressure and moreover large diameter of screws provide more contact area with threads of jaws.

8. ACCURACY ADJUSTMENT CHUCKS

These chucks are available with 3 jaws and 6 jaws and are referred as AAC-3 and AAC-6 respectively. These are used where same size of job is to be held repeatedly and accuracy desired is very high. The chuck accuracy can be adjusted within 0.005 mm with the help of micro-adjustment screws. The repetitive accuracy available with these type of chucks is within 0.013 mm. These chucks are used for tool room and grinding shop work. One set of reverse Jaws, Mounting Bolts, Allen Key, Operating Key and Inspection Report is provided with each chuck.

9. BIG BORE SELF CENTRING CHUCKS

These chucks are available with 3 jaws, 4 jaws and 6 jaws and are referred as BBC-3, BBC-4 and BBC-6 respectively. These are similar to Normal Standard Chucks, the only difference is that the bore is larger than normal Chucks. These chucks are used where machine is lighter and the job requires large bore in the chuck. One set of Reverse Jaws, Mounting bolts, Operating Key and inspection report is provided with each chuck.

10. DRILL POINTING GRINDER CHUCKS

This chuck is available with 6 jaws and is referred as DPG-6. This chuck is specially designed to grip drills for sharpening purpose. Mounting Bolts, Operating Key and Inspection Report is provided with each chuck

11. DUST PROOF CHUCKS

Dust Proof Chucks are boon for mass production workshops where dust causes periodic breakdown in chucks, thus reducing productivity. This new design of scroll operated self centering chuck has serrated base jaws mountable with reversible Top Hard Jaws or Top Soft Jaws. The serrated base jaws have a limited movement and are also sealed against any dust entry into the chuck.Therefore the life of the Dust Proof Chucks is increased by 60% and also the loss in productivity because of essential periodic cleaning of chuck is eliminated. This saving in terms of increased productivity and increased life of chuck makes Dust Proof Chuck an indispensable equipment for any mass production workshop.

12. POWER CHUCK ( CLOSE CENTRE )

CLOSE CENTRE POWER Wedge Hook Chucks are designed to suit highly productive automates,

capstans and CNC Lathes. Its rugged design is complemented with precision. All wearing

surfaces are hardened and precision ground and parts are made of Ni, Cr STEEL for LONGEVITY,

The serrations of master jaws and top jaws are ground to achieve precision grip with hard jaws also.

CLOSE CENTRE POWER CHUCK mainly used in those jobs whose are smaller in sizes or not requires

through bores.

POWER CHUCKS are available in 125,135,160, 200, 250 & 315 mm sizes.

13. POWER CHUCK ( OPEN CENTRE )

OPEN CENTRE POWER CHUCKS used for higher productivity, Its rugged design is complemented with precision. All wearing

surfaces are hardened and precision ground and parts are made of Ni, Cr STEEL for LONGEVITY,

The serrations of master jaws and top jaws are ground to achieve precision grip with hard jaws also.

POWER CHUCKS are available in 125,135,160, 200, 250 & 315 mm sizes.

14. 2 JAW SELF CENTRING CHUCKS

These chucks having 2 jaws which were used holding special kind of jobs or to hold fixture , these chucks mainly used in sanitary line mainly Tap , Showers etc .

15. COOKER TYPE CHUCKS

These kind of chucks used in Utensils factory .

These chucks mainly used in making cookers , frying pans, pans etc .

Chucks available in 3, 4, 6 Jaws , comes in 160mm, 200mm, 250mm .

16. HEAVY DUTY INDEPENDENT CHUCKS upto 7feet

INDEPENDENT CHUCKS Offenly uses in heavy industries where job is huge in nature . these chucsk are heavy duty , Rigid in nature .

17. ECENTRIC COMPENSATED POWER CHUCKS

These eccentric chucks have been designed to hold work piece in between centers having eccentricity or irregularity. These compensating chucks provide total solution to any chucking problem that requires the jaw movement to be compensated to match the eccentricity or irregularity of the work piece.

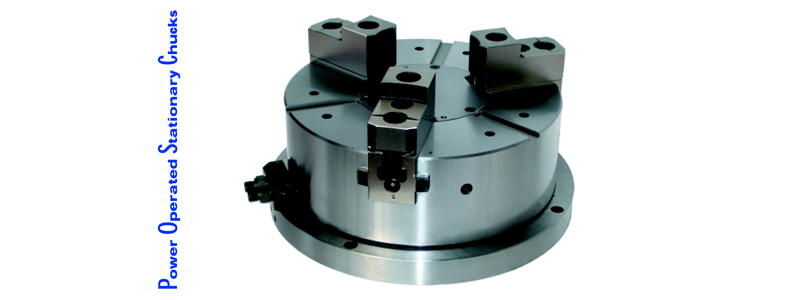

18. STATIONARY POWER OPERATED CHUCKS

Thease chucks are exclusively designed for drilling machines,milling machines and vertical

CNC machining centers. The compact construction of these machines provides maximum working

space,which allows inspection of components in clamped or unclamped positions.

These chucks with a built-in cylinder can be operated pneumatically or hydraulically with

a flexibility of using in vertical positions.

19. 6 JAWS INDEPENDENT CHUCKS

These chucks used in special purpose jobs for higher gripping , rigidity , durability . also for higher production of special purpose jobs .

20. SUPER THIN SQUARE ROUND MANUAL CHUCKS

These chucks designed specialy as per customer requirment . these kind of chucks mostly uses in those kind of jobs who need to special treatment . job having small area of clamping , or in those machines who having less space moving with jobs .

21. SPECIAL 8 JAWS CHUCKS

These chucks designed for special purpose .

22. CLOSED CENTRE ROTARY CYLINDER

Compact design reduces the weight on the machine spindle and maintains outstanding stability during high-speed operation. It is ideal for high-speed CNC chucking lathes. It is also suitable for Front or Rear mounting. The oil supply system in the distributor housing allows a little oil leak out, to ensure continuous lubrication of the bearings and avoid heat generation.

23. HOLLOW ROTARY CYLINDER

It is ideal for high-speed CNC chucking lathes. It is also suitable for Front or Rear mounting. The oil supply system in the distributor housing allows a little oil leak out, to ensure continuous lubrication of the bearings and avoid heat generation.